Ozone Generators

Introduction

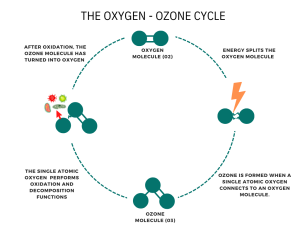

The molecule of ozone is composed of three negatively charged oxygen atoms. After a while, the ozone molecule falls back into its original form due to its instability and short half-life. Ozone generators produce ozone (O3) by applying an electrical charge to the oxygen molecules (O2) passes through which causes the oxygen atoms to part ways and temporarily recombine with other oxygen molecules. Industrial ozone generators have cells designed to diffuse electrical discharge through a dielectric material to generate ozone.

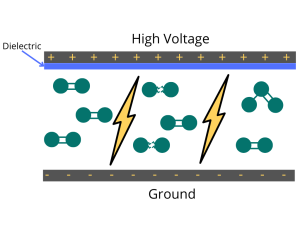

An Ozone cell work simply by diffusing a spark through a dielectric to spread out the electrical discharge to a large area.

Corona discharge versus Plasma Ozone

Corona Discharge occurs when the gaseous air mixture (~21% oxygen) around the conductor is ionized by an electrical discharge. Corona Discharge Ozone generators can generate ozone gas concentrations of 3-5% depending on the configuration and do not require high concentrations of oxygen.

Plasma Ozone Generators work on the principle of dielectric barrier discharge in which electrical currents are utilized between an anode and a cathode, through a pure oxygen source (~95% purity) creating an electric field. As the electrical charge passes through the oxygen, it ionizes the gas to a point where it becomes electrically conductive and forms a Plasma. Plasma Ozone generators require high concentrations of oxygen and can generate ozone gas concentrations of 10-15%.

Benefits of plasma over corona discharge ozone generation

- Plasma Ozone Generators offer higher ozone gas concentrations in a smaller footprint than the equivalent Corona Discharge Ozone Generators.

- As Plasma Ozone Generators operate using a pure oxygen feed, they are not susceptible to the fluctuations in Ozone gas concentration that is commonly found in Corona Discharge Ozone Generators.

- Plasma Ozone Generators do not form corrosive and toxic nitric acids as the feed gas do not contain Nitrogen and is generally free of moisture.

- Plasma Ozone Generators generate less heat as compared to a Corona Discharge Ozone Generator of the same capacity.

Ozone Generator Cooling:

There is an energy transfer involved in converting oxygen to ozone. The process produces heat as a by-product. Heat must be removed from the ozone generator either by air-cooling, water-cooling, or both.

Air-cooled ozone generators are simple and require fewer overall system components. Air-cooled heat rejection systems are almost maintenance-free. Only sporadic periodic cleaning of air vents and condenser coils might be needed if the air-cooled system is operating in a dirty environment

Water-cooled ozone generators add capital expense and require cooling water passing near high voltages used for ozone production. In addition, the quality of the cooling water is important to prevent scaling of the heat exchange surfaces and/or corrosion of the generator. Also, elevated chloride levels in the water can result in corrosion. Water-cooled systems also have operation and maintenance issues; although it mostly depends on the quality of water used and surrounding conditions.

Therefore, air-cooled ozone generators are commonly used for small to mid-sized ozone applications. Absolute ozone generator offers a highly efficient air-cooled generator with ozone production up to 200g/h and concertation up to 22%.

Other Components of the ozone system

These devices take in ambient air, automatically filter (remove dust particles), then separate and remove nitrogen (thereby leaving air considerably enriched with oxygen), which is also dried to below the desired maximum dew point (“4°C), all at the same time in one small device. These oxygen concentrators operate on the principle of pressure swing adsorption (PSA) drying. Today most of the ozone generating systems use oxygen as the feed gas because the concentrations of ozone produced are increased two to three times for the same energy expenditure.

Flow meters and filters

Mass flow meter provides accurate measurement of total oxygen gas flow from the oxygen concentrator to the ozone generator. The ozone flow meter uses a small gas stream (less than 2 LPM) to measure ozone flow and regulate gas flow through an ozone generator or injection port. Although oxygen concentrations normally have integrated filters, external filters are recommended to ensure that ultra-pure oxygen is entering your ozone generator.

This device will be used for measuring the ozone concentration percent by weight, or g/m3. Different types of ozone monitors are used depending on the objective and point of use. Ambient safety monitors are instruments to monitor the amount of ambient ozone at ground level or workplace in industrial applications, Ozone safety monitors are recommended for workplace health and safety monitoring where ozone is being produced and used. In-line ozone monitors are devices for measuring the output of high concentration ozone gas this device is common to use after the ozone generator to obtain a precise measurement of the actual ozone concentration. A dissolved ozone monitor is a device for reliable measurement of the ozone concentration in water and controlling ozone treatment systems this device.

Ozone mass transfer is the movement of a gas phase into water. In most Ozone applications, ozone needs to be dissolved into water. Ozone gas is partially soluble in the liquid. However, using proper methods and equipment high mass transfer efficiencies can be reached. Ozone can be transferred by either bubbling or mixing with a venturi mass transfer system. Initially, diffusion stones were the primary method for transferring ozone mass to water. Currently, venturi-based mass transfer systems are the preferred method for dissolving ozone in water due to their simplicity, economy, and effectiveness. In addition, a venturi injector has about 90% efficient and can be up to 99% efficient at dissolving ozone into the water.

To prevent serious damage to the ozone generator and to protect your investment, do not install an ozone generator without a flood preventing the device if water is present in your application.

At the outlet of the destructor, excess ozone is destroyed, and the cleaned and decontaminated air is re-circulated to its intended enclosure or discharged to the ambient atmosphere. Excess ozone can be broken down into oxygen and sent into the atmosphere to prevent any harm to the worker. Ozone at high concentrations is corrosive and toxic even at lower ppm. In this device, the excess ozone is allowed to release into the air such that the contact of both is controlled.

Since ozone is unstable in the air, decomposition of ozone takes place and oxygen is given out through the outlet. The AOD series Ozone Destruct Unit utilizes a thermal-catalytic method to remove excess ozone. The catalyst is a transition metal manganese dioxide/copper oxide material. It is not consumed by the ozone and acts as a true catalyst.

Send Us A Message